- High Precision Linear Encoded Closed Loop Drive System on ALL 4 axes of movement providing repeatable accurate placement. 5μm resolution on X, Y & Z axes. 0.036° on R.

- Precision ground linear guides on all axes.

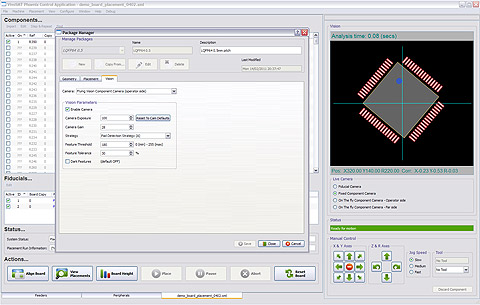

- High Resolution video camera based vision system for component orientation, fiducial and part identification. Sophisticated adaptive geometry based detection algorithms for consistent and reliable results.

- On the fly component camera for increased machine throughput.

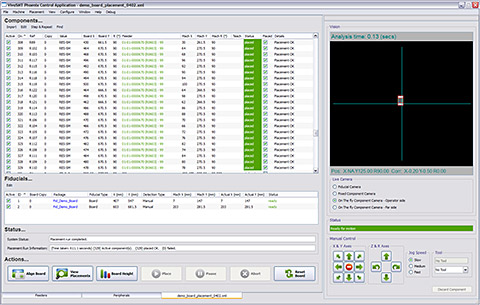

- User friendly & intuitive feature rich windows 7 based user interface.

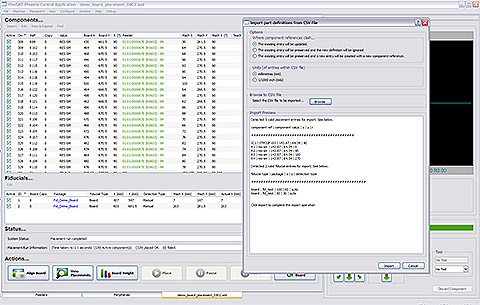

- Easy board setup using either CAD import, direct entry or Manual Teach.

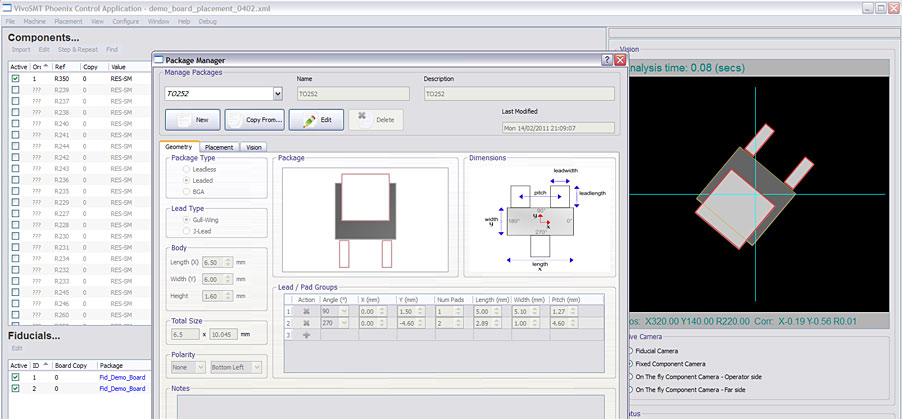

- Fully configurable component package library. Creating new component definitions is a breeze.

- Intelligent microprocessor controlled feeders that store part information and contain on-board drive system.

- Feeders can be plug and played in any feeder port with minimal feeder setup required and quick and easy loading.

- All feeders are single lane for increased flexibility, reduced changeover time and reduced capital cost.

- Automatic feeder assignment to part placement based on component names and their user configurable aliases.

- 5mm thick section 100mm square steel tubing frame for class leading strength and vibration damping.

- 12 Position tool-changer supporting standard and custom tools that cover all known component package types.

- Remote diagnostics for ease of servicing and support.

- 12 month warranty as standard with a wide range of post warranty service & support options available.

- Unlimited no-quibble feeder lifetime swap-out warranty.

British designed and manufactured SMT Placement machines for prototype through to medium volume production.

Local Sales, Service & Support direct from a UK based manufacturer with a proven track record and a substantial user base. Machines available from stock.

Easy to use, Intelligent & engineered to grow with your business at a refreshingly affordable price. By cutting out the usual distribution channels we can supply fully configured machines from just £29,950 and Intelligent Feeders from £295 to ensure a rapid return on your investment. Our finance packages start from just £150 per week.

New to Automated Surface Mount Assembly? We can provide hands on assistance to get you into profitable production within a matter of days. Find out what makes our customer service and support second to none.

| Placement Specifications | |

|---|---|

| Placement Area | 1200 x 330 (mm) |

| Placement Rate (Max.) | 3000 - 5000 CPH depending on head configuration |

| Placement Accuracy | 30μm |

| Minimum Component Size | 0.5mm x 0.3mm (0201) |

| Maximum Component Size | 28mm2 (high res fixed camera) or 50mm2 (super high res fixed camera). |

| Minimum Component Lead Pitch | 0.4mm (0.016") |

| Component Alignment | CCD Camera |

| Unlimited Placement Angle | Yes |

| Toolchanger | 12 Position (std) |

| Tool Nozzle Sizes (internal diameter) | 0.3mm - 4mm |

| Supports Custom Tools for Odd components | Yes |

| Vacuum | Venturi based integrated unit with adaptive vacuum control, blow-off, filter |

| Height Sensing | Vacuum detection solid-state temperature compensated |

| PCB Specifications | |

| Loading Method | Manual. (Conveyor option) |

| Maximum PCB Size | 1200 x 320 (mm) |

| Minimum PCB Size | 5 x 5 (mm) |

| Fiducial Recognition | Automatic - Vision based. |

| Min fiducials required | 2 |

| Fiducial Types | Automatic (vision detection) or manual (taught position) |

| Board Alignment | Trigonometric or Warp Matrix configurable |

| Automatic Board Scaling | Yes |

| Feeder Specifications | |

| Max. number of dynamic feeder ports | 128 |

| Max. number of static feeder ports | unlimited |

| Fully intelligent P&P feeders | Yes |

| Automatic feeder assignment | Yes via component names and aliases |

| Communication Method | Proprietary CAN based |

| Vision System | |

| Fiducial / Flying Vision Camera | Sony CCD VGA with Computar C Mount Lens |

| Fixed Component Camera | Sony CCD VGA with Computar C Mount Lens |

| Analysis Software | Proprietary - Built on Intel OpenCV libraries |

| Illumination | Custom High intensity LED lighting rings and diffusers |

| User Interface | |

| Operating System | Windows 7 Professional |

| Monitor | 22inch LCD |

| Keyboard, Mouse | Yes |

| Placement Entry | Fully customisable CAD import & Manual Teach |

| Placement Preview | Yes with package overlay |

| Placement Position Nudge | Yes via hotkeys |

| Numeric Data Entry | Yes |

| Step & Repeat | Fully customisable including copy entry editing |

| Offline programming | Yes |

| System Auditing | Comprehensive log file support |

| Remote Diagnostics | Yes |

| Mechanical Specifications | |

| X/Y Axis Drive | AC Brushless Servomotors with adaptive PID control & Renishaw linear encoders |

| X/Y Resolution | 5μm |

| Z Axis Drive | AC Brushless Servomotor with adaptive PID control & optical encoder |

| Z Axis Resolution | 5μm |

| R Axis Drive | AC Brushless Servomotor with adaptive PID control & direct drive optical encoder |

| R Axis Resolution | 0.036° |

| Dimensions | |

| Overall Dimensions Approx | 1530mm long x 950mm wide x 1750mm high |

| Recommended Installation Footprint | 2500mm x 2000mm |

| Weight Approx unladen | 500 Kg |

| Weight Approx with 128 feeders | 700 Kg |

| Supply Requirements | |

| Electricity Supply | 220-240 VAC 50/60Hz 1kW Nominal (single phase) |

| Air Supply | 6.5 bar 45 l/m clean filtered |

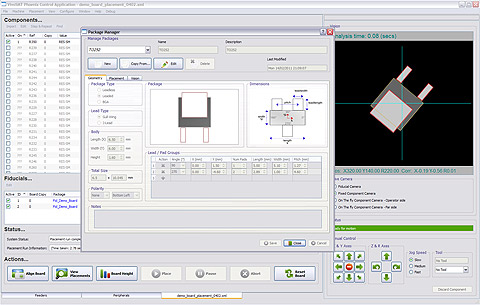

User friendly & intuitive user interface

Our machine control software was developed in-house from the ground up to be intuitive and easy to use. Running on windows 7 professional it provides a familiar environment for your machine operator and has a simple uncluttered workflow. Our policy of frequent releases enables us to quickly turn customer suggestions into features.

If you come up with a great idea for an enhancement, it will get implemented.

Easy board setup using either CAD import, direct entry or Manual Teach

CAD data import is the preferred method of defining a board’s placement positions. Our CSV import module can be easily configured to work with data supplied by most PCB layout packages, regardless of their output format. The bottom line is if they can output as a text file, we can read it.

Alternatively, placement entries can be created by direct entry or by manually jogging the machine to teach the placement locations. Step and repeated panels are easy to configure and simple to edit.

Sophisticated Geometry based Vision System

Our proprietary geometry based feature detection uses an approach that is more robust and far less susceptible to lighting variations compared to library image based systems.

This results in superior component orientation correction and the results are automatically fed back to the feeder to adjust subsequent picks. Although being powerful the system is easy to configure and provides for consistent placement accuracy.

Fully configurable component package library. Creating new component definitions is a breeze.

Our component package manager comes preloaded with definitions for most common packages. Creating a new package from scratch or copying from an existing one is a doddle.

1200mm x 330mm. Apart from a small area taken up by the toolchanger and fixed camera the entirety of the rest of the bed can be used for whatever you like. PCB’s, matrix trays, cut strips, custom jigging. Whatever you choose.

This means that you can populate the largest boards and panels you can lay your hands on!

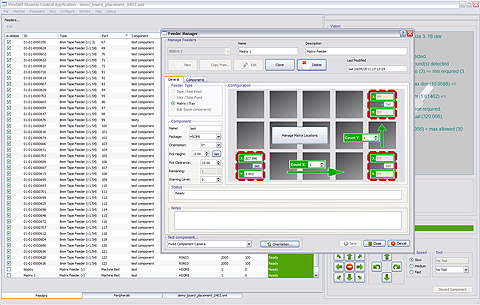

Intelligent Tape Feeders

Single lane Fully Intelligent Tape Feeders available to suit 8mm - 72mm wide tape. Our microprocessor controlled tape feeders exhibit features more akin to those found on high end machines but at a very affordable price. Unlimited pitch adjustment, onboard drive, component definition stored in non-volatile memory. Plug and play on any machine feeder port. Find out more...

Intelligent Stick Feeders

Single lane Fully Intelligent Stick Feeders available to suit all common stick/tube components. Using the same onboard microprocessor as our intelligent tape feeders these feeders feature all the configuration options you will ever need at a sensible price.. Variable drive frequency, drive duration, component definition stored in non-volatile memory. Plug and play on any machine feeder port. Find out more...

Matrix Tray & Cut Strip Feeders

Matrix Trays and Cut lengths of tape are defined through the machine’s user interface. To set up you simply jog to the opposite corners of the tray and input the numbers of columns and rows. The software does the rest for you. There’s no limit as to how many you can have setup. Enabling/disabling is one click away and replenishing individual locations or the entire tray is a breeze. Also, just like our intelligent feeders they can automatically be assigned to placements via their name and/or component aliases. We can provide tray supports and also offer a custom tooling/jigging service should you need it. Find out more...

Please call us on 01908 888254 to discuss your application and to arrange a no obligation demonstration.